Since 2021, Ancora has been part of the development of the SARATROF project (Analytical System for the Aggregate Performance of Workers and Robots in Manufacturing Operations) in collaboration with Situm, Ledisson, EDNON, and BETA Implants. SARATROF is co-financed by the Xunta de Galicia and the European Union under the Feder Galicia 2014-2020 Operational Program.

The project aims to create an analytical tool to characterize factory performance by aggregating the behavior of robots, machines, IT systems, and workers. The objective is to increase production capacity.

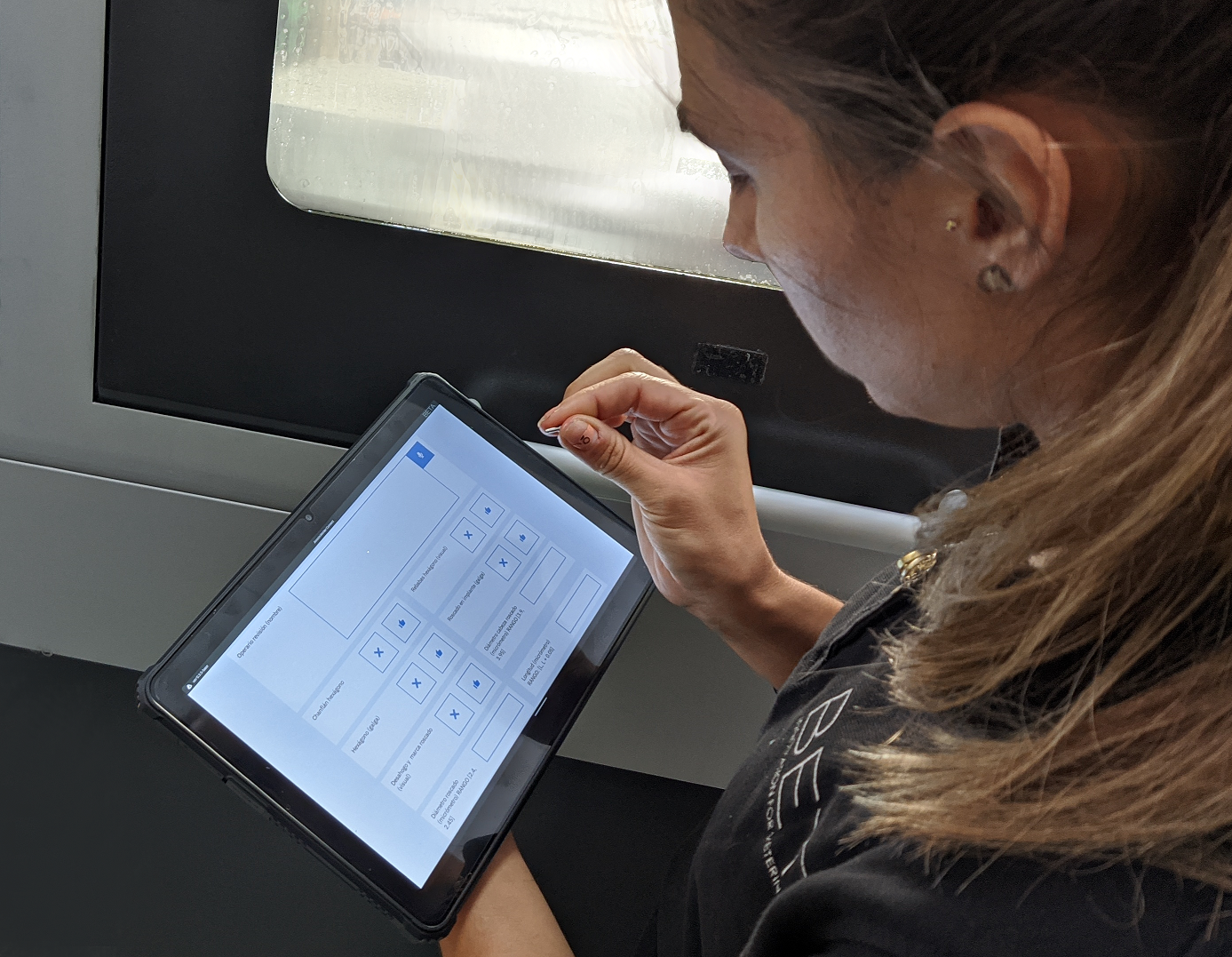

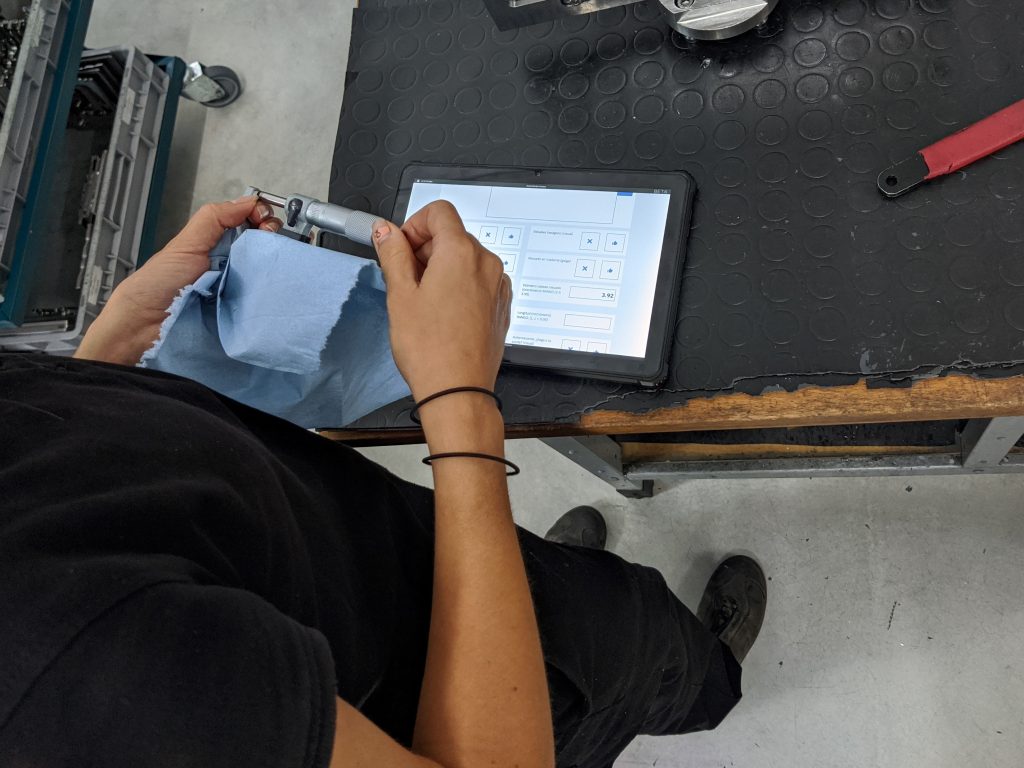

Ancora Worker Connect, Digital Workstation at BETA Implants

In 2022, Ancora and BETA Implants (Biomechanical Engineering & Technical Assistance) collaborated on the deployment of the Ancora Worker Connect solution at the plant of this innovative manufacturing company, which is a global reference in the production of prosthetics and the development of innovative solutions for the veterinary sector.

Implementing the digital workstation at BETA Implants through Ancora Worker Connect has enabled the capture of operation, activity, and downtime traces from workers, which are processed, stored as objects, and uploaded for analysis in the meta-platform developed by EDNON. A series of direct indicators are then computed. The captured traces range from manually input data collected directly from the user via production and quality forms to system-generated usage traces.

This deployment was initially carried out as a pilot at the BETA Implants plant in Salvaterra de Miño, with plans to extend it to new facilities to support the company’s growth in the coming years.

How the Data Collected by Ancora Worker Connect is Transformed

The usage traces of Ancora Worker Connect are collected in real-time using a node-RED WebSocket. The incoming data is processed dynamically, enabling the capture of the most relevant usage traces and automatic task input by the worker within the interface.

After processing, the traces are uploaded to the meta-platform to be combined with deposition traces captured by Situm and with traces from milling machines and lathes captured by Ledisson. This enables cross-analysis to derive more comprehensive insights about the worker.

For the analytical processing of these traces, task classification models and regression models have been developed to predict task times. These models now generate performance analytics.